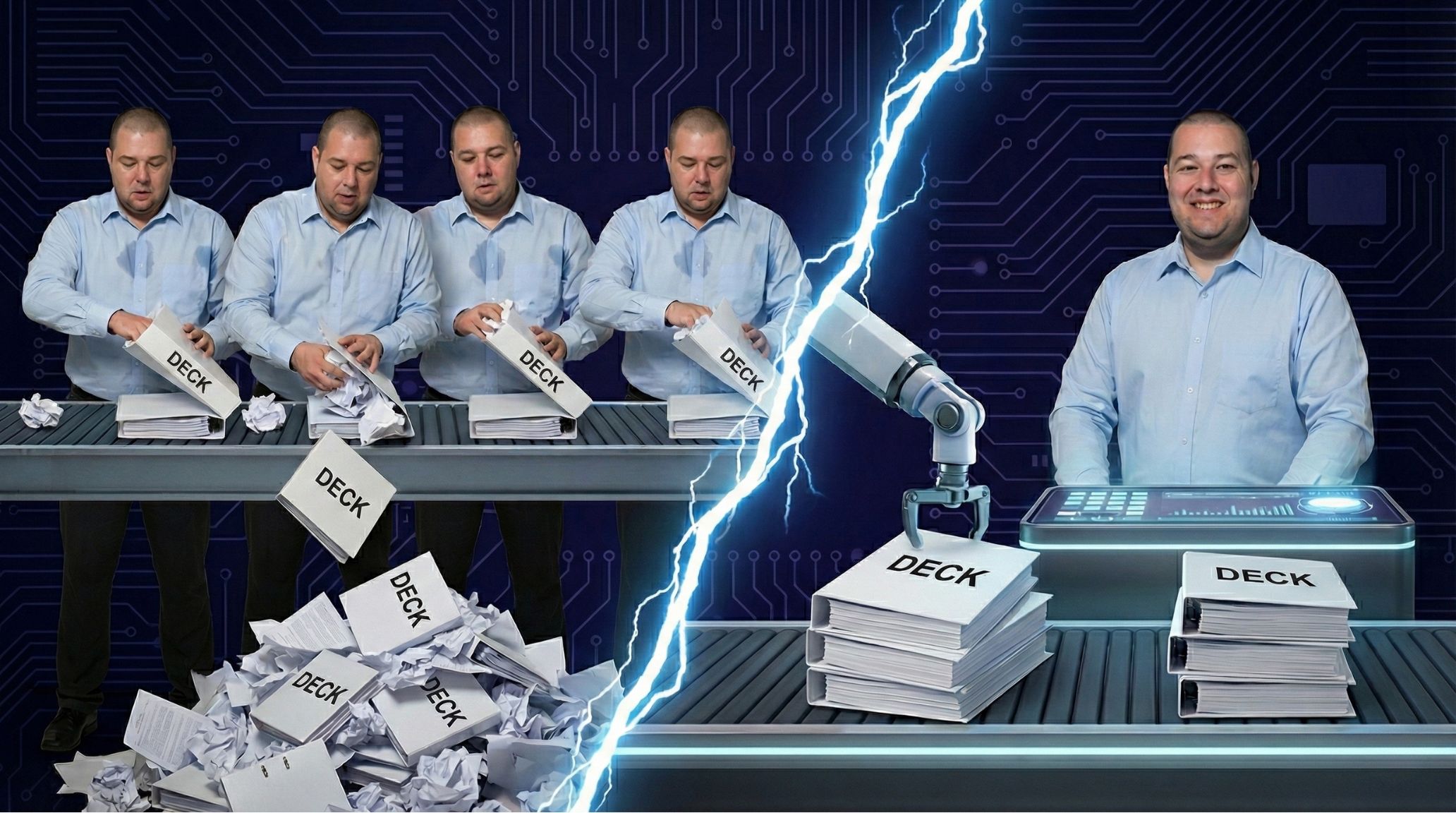

The Board Deck Assembly Line: Manual vs. Automated

Every month, finance teams around the world assemble board decks. The process looks roughly the same everywhere:

- Export data from ERP

- Open last month's PowerPoint/Excel

- Update numbers manually

- Rebuild charts

- Write new commentary

- Format everything

- Convert to PDF

- Distribute

This is the assembly line. It runs every month. It consumes enormous hours.

And most of it shouldn't be manual.

The Current Assembly Line

Let's break down a typical board deck assembly:

Hours 1-2: Data extraction. Export trial balance. Export AR aging. Export cash position. Save files in the right folders.

Hours 3-4: Template update. Open last month's deck. Save As new month. Update date headers. Clear old commentary.

Hours 5-7: Number input. Copy-paste from exports into template. Update formulas. Fix the ones that break.

Hours 8-9: Variance calculation. Calculate budget vs. actual. Calculate prior year vs. current. Calculate month vs. prior month.

Hours 10-12: Visualization. Update charts with new data. Resize as needed. Fix formatting issues.

Hours 13-15: Commentary. Write explanations for variances. Add context for trends. Include recommendations.

Hours 16-17: Quality check. Verify numbers match source. Check totals. Spot-check formulas.

Hours 18-20: Finalization. Format for readability. Convert to PDF. Distribute to stakeholders.

20 hours. Every month. Much of it repetitive.

What Should Be Manual

Some of this work genuinely requires human judgment:

Commentary: Explaining what happened and why requires understanding context that systems can't know.

Recommendations: Suggesting actions based on the numbers requires strategic thinking.

Quality check: Human review catches things automation misses.

Stakeholder management: Knowing what to highlight for which audience is judgment.

These tasks deserve your time. They're high-value work.

What Shouldn't Be Manual

The rest is mechanical:

Data extraction: If you're manually exporting, your systems aren't integrated.

Template updates: Date headers, period labels, file names—all automatable.

Number input: Copy-paste from export to template is what computers do better than humans.

Variance calculation: Math. Just math. Computers excel at math.

Chart updates: If the data updates, charts should update. Automatically.

These tasks consume time but don't require expertise. They're process, not judgment.

The Automated Assembly Line

An automated board deck assembly looks different:

Hour 0: Data refresh happens automatically. Template pulls directly from ERP.

Hour 1: Review pre-populated deck. Verify numbers look reasonable. Check for unmapped accounts.

Hours 2-4: Write commentary. Explain the variances. Provide context.

Hour 5: Final review. Confirm quality. Approve for distribution.

Hour 6: Publish. One click. Distributed.

6 hours instead of 20. Same deliverable.

Where the Hours Go

In the automated model:

- 0 hours on data extraction (automated)

- 0 hours on template updates (automated)

- 0 hours on number input (automated)

- 0 hours on variance calculation (automated)

- 0 hours on chart updates (automated)

- 4 hours on commentary (human value)

- 1 hour on review (human judgment)

- 1 hour on distribution (human decision)

The work that requires humans gets human time. The work that doesn't gets automated.

The ROI Calculation

14 hours saved per month × 12 months = 168 hours per year

At $75/hour (loaded cost for a senior analyst): $12,600 per year

For a team of 3 doing similar work: $37,800 per year

This isn't speculative. This is arithmetic. The savings from automating board deck assembly are substantial and immediate.

The Quality Improvement

Automation doesn't just save time. It improves quality.

Consistency: Automated processes don't vary. Every month follows the same steps.

Error reduction: Copy-paste errors disappear when there's no copy-paste.

Earlier availability: When assembly is faster, decks are ready sooner.

More review time: Time saved on production goes to verification.

The CFO who gets a board deck on day 5 instead of day 12 has more time to review and refine.

The Resistance

Why don't more teams automate?

Change cost: Building automated processes requires upfront investment.

Tool uncertainty: Which tools to use? How to integrate them?

Process ownership: "We've always done it this way" is powerful inertia.

Perceived risk: Manual processes feel controllable, even when they're error-prone.

These barriers are real. They're also surmountable.

Your Starting Point

Map your current assembly line. List every step. Time each one.

Categorize: Does this step require human judgment, or is it mechanical?

The mechanical steps are your automation opportunity. Start there.

The board deck assembly line runs every month. You can either run it manually forever, or invest in automation once.

The choice is a math problem. The math is clear.